Electronic Industry

SMT SCREEN PRINTER

- HP-520SPI

- HP-520s/HP-680S, HP-850s/HP-1000S

- Hp-350MD/HP-680SD

- HPX-1300S

- HP-520E

ATF _ ATF GmbH is leading experts in processing ,producing and distributing Wave Soldering, Selective Soldering ,Vapour Phase Soldering Systems.

ATF GmbH was born from Collaboration with Electrovert, USA , The inventor of wave soldering machine.Even today ATF systems benefit from German quality

Automated and Semiautomated Stencil Printer, Pick and Place,

Reflow Soldering Systems for prototyping and R and D

Systems for Automation and Welding

(Welding Heads, Welding Guns, Compacting Tools, Battery Processing)

Poineer of "Soft X-rays"

Specialized company for non distructive inspecting using

X-rays inspection equipments. For applications solder joint conditions,

micro crack inspection, BGA inspection resin fiber flow,

void disconnection state of IC wire, cable etc.

SHR Series/WL Series/SFX Series/ CT Unit

Juki Smart Solutions

High Speed, High Quality, SMT Mounters

Placement Monitor, Electric feeder series

R-Series/FX/KE/KD Series

High Precision 3D Inspections Solutions

Solder paste inspection, 3D-SPI, Automatic Optical Inspection

2D-3D AOI

Factory Certified Pre-owned inspection Systems

World Class Robotic Solutions.

High Efficient, Versetile Robotic Soldering

Robotic Routing, Screw Driving Robots, Laser Marking Robots

Dispensing Robots, Collaborative Robots

Pemtron an Inspection equipment developer and supplier. Based on 3D precision measurement and vision source technology, PEMTRON develops equipment used in various fields such as SMT, Automotive Field, Lead Tab, Semiconductor, and supplies Soldering Inspection equipment (3D SPI), 3D Mounting Inspection equipment (3D AOI, MOI), Wafer Bump 3D Inspection equipment, Wire Bonding 3D Inspection equipment, and Lead Tab Process/Inspection equipment.

In addition, based on the world's best Inspection Technology, Pemtron is releasing new equipment needed by the market,such as Coating Inspection machines (CI), Pin inspection Machines, and Bottom Inspection machines, and is expanding its business to new applications such as nano and bio based on Electron Microscope (SEM) Technology.

TROI 7700 SERIES

3D Inline Solder Paste Inspection System

Using Moire' pattern, Pemtron's three-dimensional lead application dosage tester combines 2D color images with 3D measurement data to provide more detailed, near-real PCB images, unlike traditional color maps.

EAGLE 3D 8800 SERIES

3D Inline Automated Optical Inspection System

EAGELE 3D 8800 AOI applies 8-way projection for 3D measurements to all models, minimizing shadow effects errors and performing 100% 2D&3D examinations simultaneously in all FOV areas. This equipment provides near-perfect detection while significantly reducing false call.

TROI 8800 CI

Conformal Coating Inspection System

The PEMTRON CI Series addresses the limitations of the area of the inspection due to the diversity of wavelengths of the existing UV, and performs a clearly separated area of coating on various wavelengths.

Nu/Clean Inline Aqueous Cleaners

We offer the latest technological advances in cleaning including touch screen controls, cascade water knives, and high efficiency drying. The insulation and exhaust systems make the Nu/Clean the quietest and most environmentally friendly cleaner available today.

TROI 8800 CI

Conformal Coating Inspection System

Technical Devices Company offers several different DI Water Recycling Systems for your Zero Discharge, Closed Loop Cleaning needs. The Nu/Clean 510 accommodates large sized media beds and easily supplies DI Water to a full sized inline cleaner. Our Nu/Clean DI Elite or Nu/Clean DI Elite Plus are smaller sized and can easily supply DI Water to any batch or small inline cleaner. All of our DI Water Recycling Systems integrate directly with the Nu/Clean family of cleaners for easy operation and monitoring.

Nu/Clean Aqua Batch

Our first Aqueous Batch Cleaner was made in 1991 and we have come a long way since then. Today’s Nu/Clean Aqua Batch Cleaners feature the shortest cycle times we have ever offered — as short as 20 minutes! The right balance of pressure and flow make cleaning and rinsing super effective. The optimized heating and drying in the Aqua Batch will get your boards clean and dry in record time.

Nu/Era Wave Soldering

The ONLY imported soldering equipment supported by an American Manufacturer. The ONLY machines backed by a network of service personnel with Years of Experience installing and servicing wave soldering equipment. The ONLY imported machines made to the high standards of Technical Devices.

The most affordable individual Solution in market and Custom made solutions.

MP Cabinets are continuously developing dry cabinets to perfectly meet all customer requirements. These are high-tech category products, and over 40% of our cabinets are custom-made solutions. Our price/performance ratio is unmatchable. Our equipment can even cool and heat in a single chamber. As if this were not enough, it is also ready for Industry 4.0. This means that components and processes can be monitored, and intelligent cabinet access management can be employed (RFID).

Standard

Our standard dry cabinets stand out thanks to their fantastic price/performance ratio. They have been developed based on our customer requirements and are available in several versions.

High Temperature

Specifically designed for PCB conformal coating applications, the T140 offers an advanced lacquer curing solution. With heating up to 140°C, the T140 ensures quick and reliable results with a build quality never seen before.

Universal Instruments. Inspired future. Place a full range of actives & passives. on a single platform. Best accuracy at the highest speed. over the largest area. 2X the throughput. at the lowest cost per placement. Fuzion Platform. Build better. Build more. Build better. Build more. Spend less. Flexible Automation Platform. Ultimate flexibility. www.uic.com

Fuzion Platform

Fuzion® is Universal’s flagship platform, leveraging the latest generation of head and feeder technologies, and software tools for maximum performance. Fuzion solutions maximize utilization, Overall Equipment Effectiveness (OEE), and productivity while delivering the lowest cost per placement for any environment or product mix.

Radial 88HT

The Radial 88HT brings a new level of productivity to radial component sequencing and insertion, offering consistently high throughput regardless of component type.

FuzionSC Platform

FuzionSC is Universal Instruments’ next-generation semiconductor platform, offering the industry’s most precise accuracy, highest flip chip throughput, and widest component range.

Automation

The Uflex™ flexible automation platform provides exclusive value by breaking traditional automation barriers with a dramatically shortened payback period and a 50% ROI improvement. With a revolutionary architecture that enables it to be easily reconfigured in the field, Uflex is a valuable asset that speeds time to market – particularly in higher mix environments. Uflex enables user-level custom programming and simplified reconfiguration by leveraging cloud-based libraries of “Apps” (process strategies and hardware drivers) to quickly transition to the next application.

Hot Bar Bonding

The Flexbond™ high-throughput hot bar bonding platform enables the first fully automated volume solution for advanced flex circuit and other hot bar interconnect applications. It combines with Universal Instruments’ Fuzion® Platform for full-process integration, including flux transfer, high-accuracy placement and hot bar soldering.

Software

If you are looking to get more from your assembly equipment investment, Universal’s IQ360™ Factory Software Suite gives you all of the tools you need to improve the operational efficiency of your Universal Instruments production lines. IQ360 is a suite of a la carte smart factory modules designed to control, monitor and improve all aspects of factory operations for maximum productivity. IQ360 enables you to engage and participate in Industry 4.0 today – and in the future!

Advanced Process Lab

In today’s high-tech industries, knowledge makes the difference. Universal Instruments’ Advanced Process Laboratory (APL) leverages extensive process and materials expertise to address current and next-generation technology challenges and maximize competitive advantage. The APL offers comprehensive research, analytical and advanced assembly services which enable manufacturers to realize rapid product introduction, maximize yield and optimize reliability. The APL also plays a leading role in the greater electronics community, organizing research consortia, and building partnerships with academic and industry experts to identify and develop new and emerging technologies –those that will take electronic assembly far into the future.

Remanufactured Equipment

A good second-user machine can solve your manufacturing challenges at lower-than-new cost, and will likely offer better performance and more capability for your money. Broome Engineering is a division of Universal Instruments that is dedicated to providing the highest quality electronics assembly equipment and accessories. Broome Engineering is the only source for Universal-Certified remanufactured equipment and is focused on delivering a lower cost alternative that preserves Universal’s stringent quality standards and the benefits of buying new.

Markets

No matter what you’re building, Universal Instruments delivers complete solutions to help you excel in your manufacturing environment. With a comprehensive technology portfolio and the expertise to optimize your processes and factory efficiency, we’ll partner with you to ensure that you give your customers the very best while continuing to grow your bottom line.

MINI 3D LASER MARKING MACHINE main advantages of the desktop laser marketing machine include beautiful appearance, easy operation, no consumable materials, free maintenance, continuous work,low failure rate, etc.

Getech automatic router

machine gar1200

Our customers work across a wide range of industries including petroleum, mining, nuclear and water. Our data rich products, GIS solutions and trusted advisory services help our customers to achieve their business goals of cost control, operational excellence, regulatory compliance and environmental responsibility.

Getech semi automatic

router machine gsr1290

Getech semi automatic router

machine gsr1280

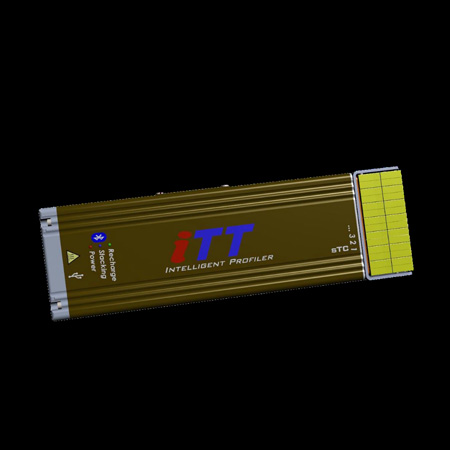

The iTT profilers are the most advanced thermal Profilers among currently existing profilers. Focused on convince, Safety and reliability of customers view, iTT profilers has proved that highest performance in both hardware and software compare to any other profiling systems.We are proud to present these innovative profilers to customers and never stop making high-end profiling system.

EXPERT 04.6 rework stations for manual rework of SMT components, SMD placement, residual solder removal, and flux or solder paste dispensing. These compact systems with precise and efficient heating are controlled by Easy-Solder eco.

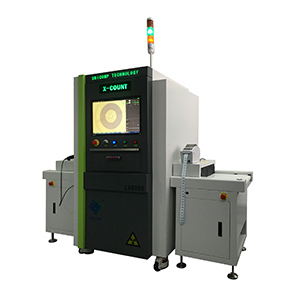

Automatic Unicomp X Ray Inline Chip Counter No Damage Less Labor

- System Accuracy: Higher Than 99.8%

- Minimum Component Size: 01005

- Count Time: Around 5s / Tape & Reel

- Inspection Size: 440 * 60mm

High Resolution NDT Industrial X Ray Machine Intelligent In - Line Detection

- Generator Voltage: 160kV

- Power: 480W

- Image Area: Φ145mm

- Resolution: 3.1LP/mm

MIRAE

Our Best Customer Service: We offer short hold times, fast email responses and instant online chat. Whatever you need from us, we'll make it easy to get.

Extra Eye Pro: X3020 / X4020

Total quality control: The Extra Eye First Article Inspection System helps you ensure your PCB assembly line is producing accurate boards, right from the start, and all the way through your production run. It streamlines every aspect of inspection, from program setup to the inspection process itself. With this easy-to-use, automated FAI system, you can dramatically shorten time-to-production, reduce end-of-line defects and improve yield. Using Extra-Eye, you’ll see lower costs and higher-quality products.

Do more, faster

- Create a new inspection program in less than a minute

- Automatically locate boards in a multi-board panel in seconds

- Locate and inspect multiple identical components with a single click

- Automatically and instantly compare entire boards to the golden board

Do more, easier

- Automate inspection, even for first boards

- Easily view even the smallest components, with automatic rotation and zoom

- Quickly and accurately inspect components added after SMT assembly

- Generate detailed documentation of every inspection

Who needs automated FAI?

Any company that assembles PCBs can gain real, bankable value from automated first article inspection. As one of the most critical steps in PCB assembly setup, FAI can stop a single small mistake from ruining an entire production run.

Extra Eye’s automated First Optical Inspection process is significantly more accurate and faster than manual inspection. With setup in minutes and easy operation, Extra-Eye FAI provides a cost-effective alternative to automatic optical inspection (AOI) for low-volume series. Comparison with golden board. With

Reflow Convenction Soldering

Rehm Thermal Systems

A global leader with innovative technologies

As a manufacturer of reflow soldering systems with convection or condensation and drying and coating systems, Rehm Thermal Systems has been producing energy-efficient manufacturing equipment for the electronics and photovoltaics industry since 1990. We also offer our customers tailor-made applications related to the soldering, coating and hardening of modules.

Safety and the right quality

For full functionality of sensitive electronics, contact between the electrical components and the circuit board, created by high-quality soldering, is essential. With the convection soldering systems in the Vision series, the soldering process is carried out on the basis of heat transfer via the flow of gases. The systems are available as air or nitrogen systems. As an inert, protective gas, nitrogen is the ideal heat transfer medium and thus prevents damaging oxidation in the soldering process. Thanks to a wide range of possible system configurations, you achieve optimum quality with the Vision series convection soldering systems, as well as maximum flexibility in terms of your production.

TAGARNO digital microscopes give you unique and easy to use magnification equipment to use in a variety of quality control processes as well as R&D efforts or in your repair and rework in an endless range of segments. The digital microscopy camera technology enables you to see any small object in ultra sharp magnification and to document your work with just a single click. It also allows multiple viewers at the same time and thereby greatly improves collaboration.

Electronics Assembly

Do you utilize an automated soldering system or execute hand soldering, and necessarily look for an air cleaning solution that meets the requirements of your processes and on-site situations? Our LRA equipment series covers the entire range of soldering fume extraction and filtration technologies – at manual work places as well as in automated and semi-automated production.

The importance of soldering fume extraction

Depending on areas of application of the finished assembly and requirements of the components, various soldering alloys and flux agents are considered. During the soldering process, large parts of the flux agent and a small portion of the solder will evaporate. The emerging aerosols and particles could be released into ambient air. These airborne pollutants are far more than just an unfortunate side effect but can lead to serious medical conditions. Particularly dangerous substances are aldehydes, which emerge from materials containing colophony; some of them may be carcinogenic. In addition, gases are released from coatings, adhesives or substrates during heating of the assembly.

These gases also transport sticky aerosols, which build up in the soldering machines or – even worse – on the products and contaminate them. This leads to increased cleaning and maintenance costs, and the operability of the plant can be impaired. In addition, the manufactured products may even be corroded by the contaminations, which could affect functionality and quality.

In order to eliminate soldering fumes, it is not sufficient to provide for only good ventilation in the manufacturing environment. The use of efficient fume extraction technology is mandatory. The variety of the available air purification systems is high. The selection of the appropriate unit depends on type and volume of pollution, the use in automated, semi-automated or manual production environments and on mobility as well as flexibility.

State of the art fume extraction units achieve such a high purification rate for the processing air that the cleaned air can even be re-circulated into the work area. We would like to support you in selecting the best suitable soldering fume extraction system. You are welcome to contact us